Read / write Coding System

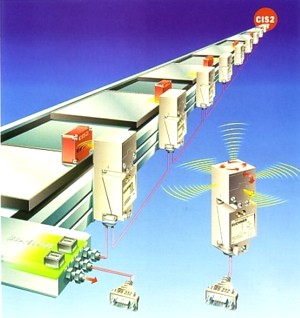

The inductive read / write coding system CIS2 from Euchner is used for contactless identification of tools, workpiece holders and pallets.

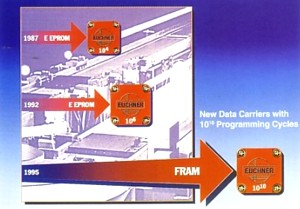

Fully compatible to EUCHNER's existing and proven miniature tool identification data carriers are the newly developed, bus compatible read / write heads and data carriers with over 10 billion programming cycles and high read / write clearance.

These components are used for controlling the flow of material and information in assembly, handling and storage technology applications.

The ground-breaking modular bus concept, with simple installation and extension possiblities, provides and ideal price/performance ratio.

Features

* Data carrier for over 10 billion programming cycles

* Up to 15mm read / write clearance

* Minimized wiring via 2-wire bus (RS485)

* Interfaces to control system via master module with 3964R protocol (V24)

* Read / write heads with serial interface

* Read / write heads with changeable direction of sensing surface.

* Simple installation and handling

* Software compatible extension of single-head connection to bus system

with 27 read / write heads